Ground fault circuit interrupters (GFCI) are commonly seen in residential wiring. They are important to understand, as they exist to protect both the users and the electrical systems used everyday.

We see ground fault circuit interrupters, or GFCI outlets everywhere in residential wiring. Some breakers even have ground fault protection characteristics. However, even though grounding is so important within industry, why do we not see every outlet outfitted with ground protection? What then is a ground fault, and what are the limitations of these outlets?

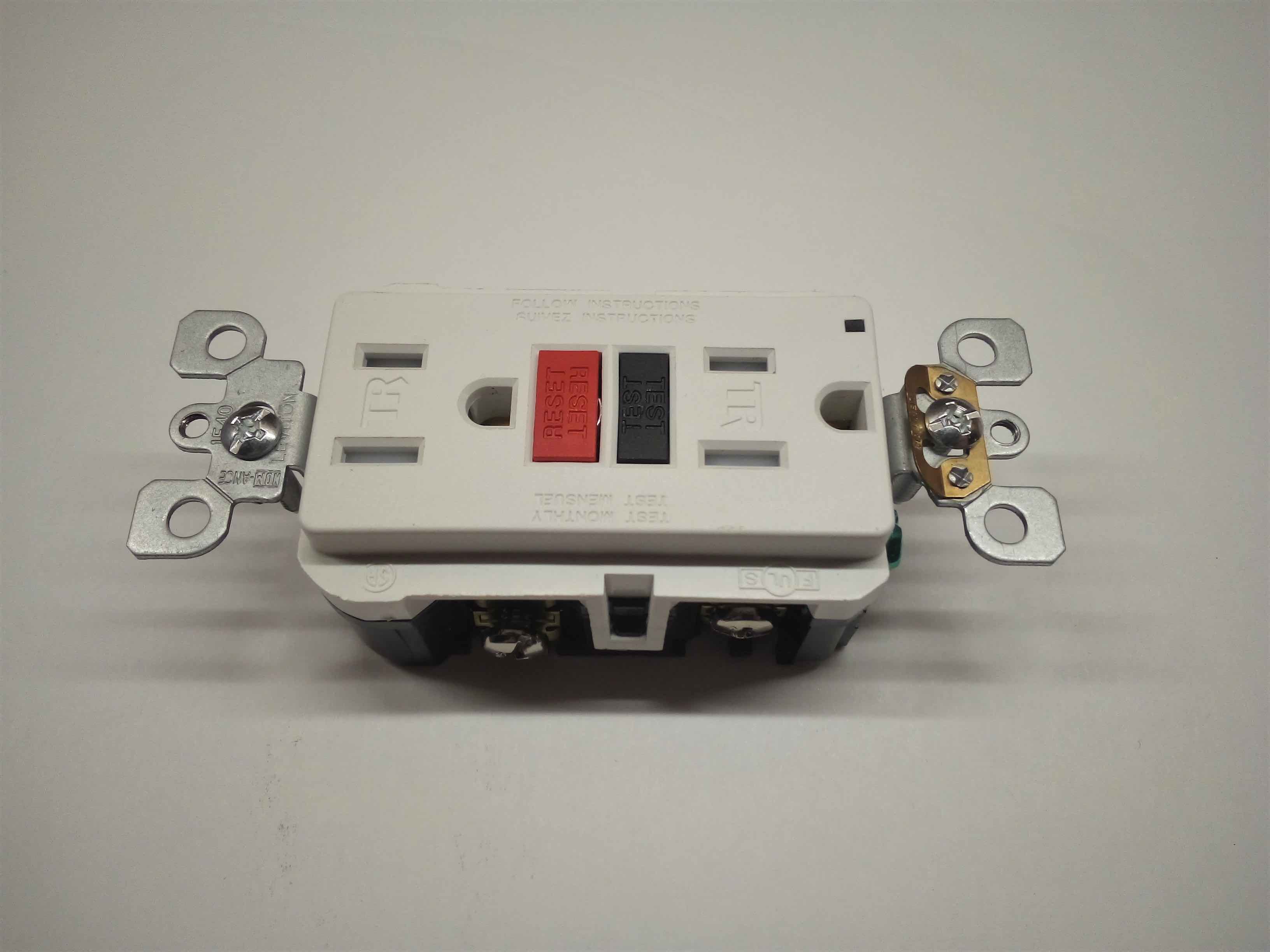

Most people have grown accustomed to seeing the outlets that have a small green LED, along with a test and reset button. They exist in every house, and often on outdoor outlets. They bear the name ground fault circuit interrupters, usually abbreviated GFCI or simply GFI. These outlets have a special function of protecting against certain types of faults, although they have limitations.

What is a Ground Fault?

Throughout an electrical system, every neutral wire is bonded to an earth-connected ground conductor. This connection happens at an electrical service panel, as well as after every power isolating device, like a transformer. In addition, nearly every metallic object is also grounded, such as electrical service panels or even the hot water heater in your house.

When the load devices are operating properly, power is supplied through the hot wire and returned to the source through the neutral wire. In three-phase systems, the power is shared — both supplied and returned — as a balance through all three hot wires.

The ground wire is never connected to any of the internal circuitry or to the load device, so there should never be any reason that the ground wire carries electricity back to the panel where it shares the neutral connection. Most of the time, the green ground wire simply attaches to the metallic case or frame of the machine with a screw and there it terminates.

That ground wire exists for the purpose of protecting against ground faults — if the internal hot wire comes loose and somehow that wire touches that grounded metal case, the device no longer functions but the electricity can now bypass the load device. A tremendous amount of current may develop, and a properly designed system will respond with the tripping of a circuit breaker or blowing of a fuse.

A typical Ground Fault Interrupter receptacle. When energized, the LED on the front will show green.

When Can Ground Faults Occur?

Ground faults can occur on equipment that vibrates or has been improperly installed — such as with an ignorance of torque specifications or wrong wire nut sizes.

As with all electronics, moisture can also be a particularly challenging case. Water or other conductive liquid can create a path from the hot wire to the case, even if no wires have come loose. Moisture can also create conductive paths from the hot wire of one machine to the ground of another, this is why wet environments must be approached with caution.

How Does a Ground Fault Interrupter Work?

A GFCI outlet must be installed properly, with a certain set of its terminals connected directly to the hot, neutral, and ground from the supply. When the circuit is active, this connection powers a set of circuitry inside the outlet and indicates function with the green LED. If power is not applied, the circuitry cannot function. So, on these outlets, you cannot press the test or reset button until power is connected.

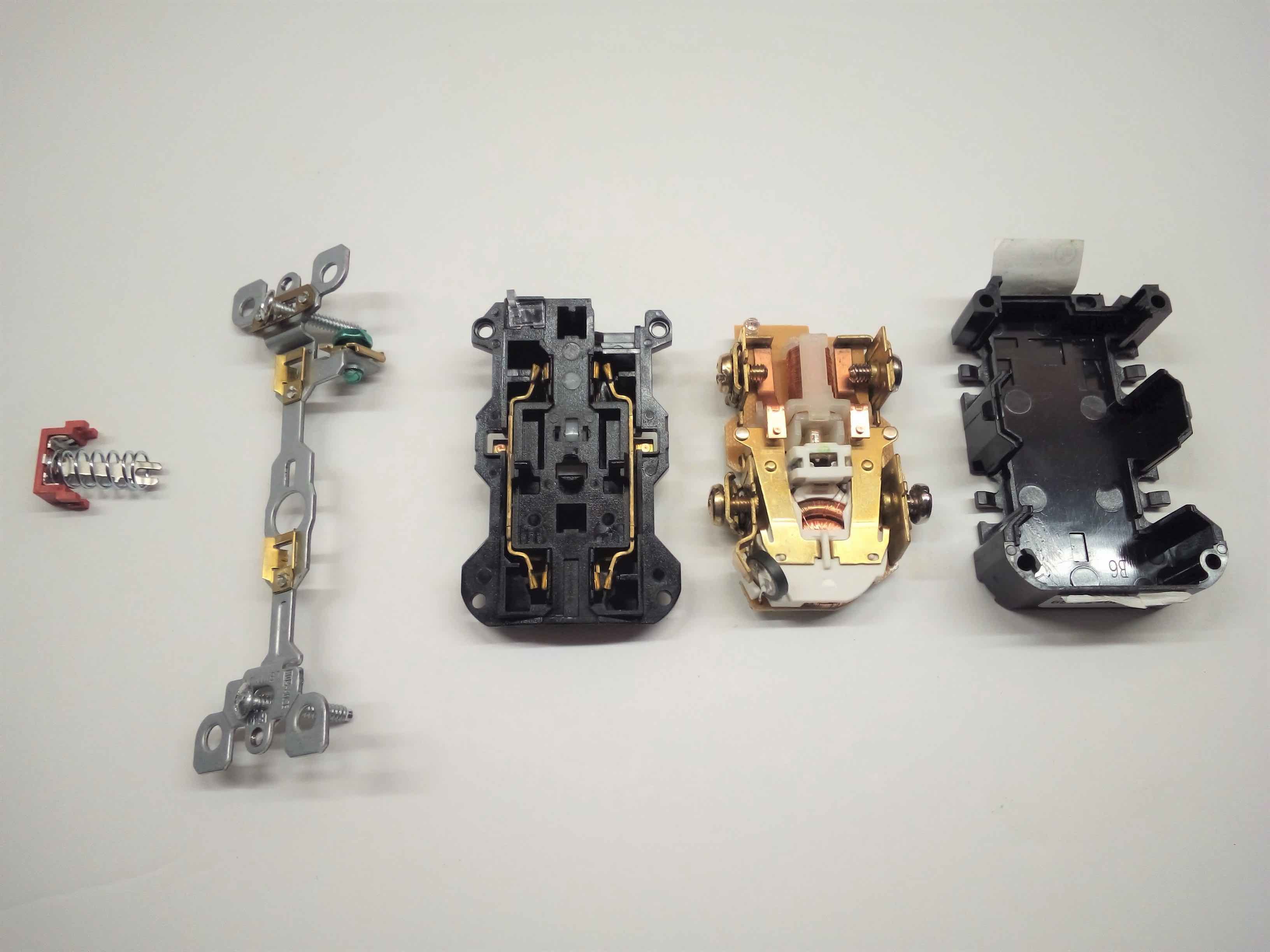

A disassembled GFCI receptacle. From left to right: the ‘Test’ button and spring, grounding chassis, upper container, sensing and disconnecting circuits, and the lower chassis.

Inside the outlet, two small inductive coils measure very precisely the current traveling through the hot wire and the neutral wire. These numbers should be equal in all cases. Whether the load is connected to that outlet, or to one downstream, all current supplied through the hot wire should return through neutral.

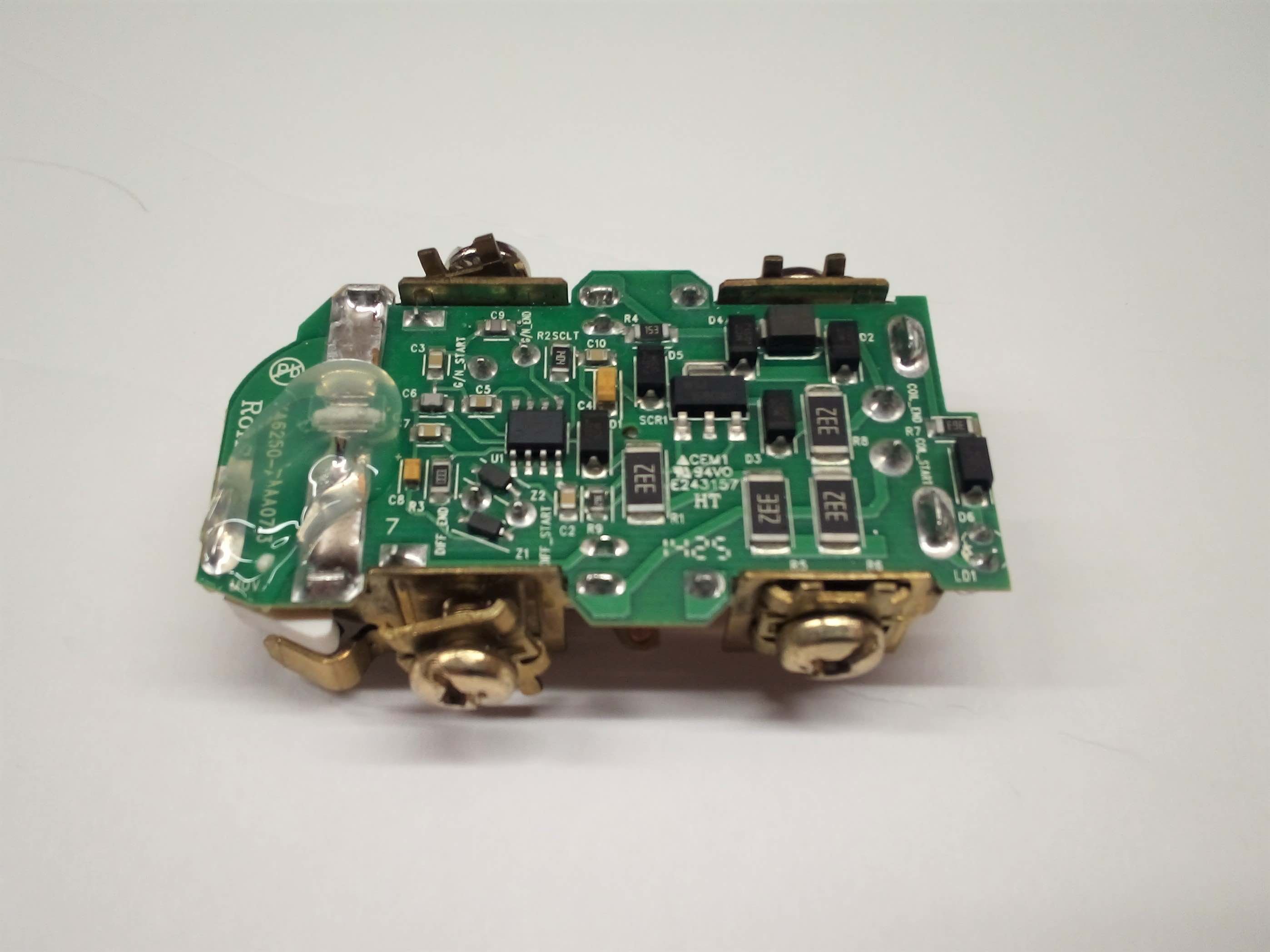

A close-up view of the internal coils and contacts of the GFCI receptacle. Near the left, the long coil is a solenoid that switches the circuit off. On the right, the two nested sensing coils detect the hot and neutral currents. In the center, contacts switch the circuit on and off, much like realy contacts.

If for any reason, the current supplied by the hot wire exceeds the current in the neutral wire by more than 5mA, it instantly disconnects the circuit with a small solenoid coil. If this excess current is sensed, it would mean that electricity is somehow exiting the circuit and returning via another ground path. If water is present, that return path may be through anything metal nearby.

Limitations of GFCI Outlets

That value of 5mA is the reason these devices are so critical in some situations, but ineffective in others.

Certainly, if a GFCI outlet was connected to supply every device, no matter the voltage or phase of the supply, it would not harm the system — rather, it would be quite safe. But the bonded ground paths already accomplish the task and the circuit breakers will trip without damage to the machine anyway. They can be conveniently placed, locked out, and then reset once the fault has been corrected. GFCI outlets would add no value to protecting machines.

However, if that ground fault has the ability to use a person as a conductor, we must be very concerned for their safety. A current of only 10mA has the ability to cause very painful shocks and muscle contractions. Above 10mA, it’s reaching varying levels leading to fatality. If the ground fault occurs when a person is present and that person happens to be between the fault and the return path to ground, they can be killed.

The fairly complex back view of the sensing circuit PCB, contained inside a GFCI receptacle. The circuitry compares the currents of the live and neutral wires.

Normal circuit breakers trip when the current exceeds 15A – 20A, or perhaps over 100A for many machines. This would far exceed a fatal current. What good is a circuit breaker for protection if the operator was killed long before excess current was reached? The purpose of the GFCI outlet is to trip the circuit if that current failure is more than 5 mA, a slight bit of shock may be felt, but that’s it.

When Should a GFCI Outlet be Used?

There are a few areas where GFCI outlets are required. First, by requirement from NFPA 70 section 210.8, they must be used in any location where moisture is an issue, including but not limited to bathrooms, outdoors, garages, sinks, and laundry rooms. Second, they may optionally be used for any outlet where the load may experience ground failures while an operator is nearby if that operator may become exposed to that electricity.

GFCI outlets do not exist for three-phase equipment, so they cannot be used there. They also would not be installed for single-phase equipment exceeding 20A (or the rating of the GFCI outlet) or anywhere a person would not be exposed to a ground failure without already having proper safety steps implemented.

A Quick Summary of GFCI Outlets

GFCI outlets are a standardized way of protecting human operators from injury and death resulting from an accidental connection from live electricity to ground. They are most heavily emphasized in areas where water may cause more rapid failure, and where human operators are not expected to utilize proper safety and PPE practices to keep themselves safe.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: admin@eleok.com