The supply chain is a vast network, from raw materials to components and finished goods. Learn what types of AI algorithms are employed to predict disruptions and enhance optimization.

The global supply chain is a highly complex network of businesses, resources, and technologies to create goods and ensure their efficient delivery. The COVID-19 pandemic and its subsequent post-era severely disrupted the global supply chain.

During the first months of the crisis, consumer demand for many products changed dramatically. Some commodities, such as gasoline, saw demand plummet immediately. At the same time, items like face masks and hand sanitizer became overnight necessities.

Disruptions of similar magnitude occurred as society transitioned back to its normal lifestyle. Demand for travel and tourism spiked, while temporary COVID-related necessities returned to previous levels.

Figure 1. The global supply chain is a complex, interconnected network.

One silver lining of an era full of challenges was the accelerated transformation towards digitalization throughout the supply chain. Businesses sought to invest in innovation with the goal of being able to predict future disruptions and create better plans to prepare for them. While the pandemic was a worst-case scenario of the unexpected, businesses do face supply chain challenges daily, and this highlighted many of the opportunities for improvement.

In this article, we will look at how a digitalized supply chain model enhanced with powerful AI algorithms enables a business to predict, plan for, and recover from disruptions.

Demand Forecasting

Demand forecasting is a powerful tool that enables businesses to peer into the future. It helps plan and maintain optimal inventory levels while ensuring on-time product deliveries. It is also much more than a simple guess; rather, it is a complex strategic process that analyzes data from multiple sources: sales data, market trends, external factors, and even social media.

Statistical Model Methods

Traditional demand forecasting methods have relied on historical datasets and simple statistical models. The first problem with this approach is the relatively static nature of the data and the analysis. The modern supply chain network introduces changes and challenges that require real-time analysis. The other problem is that the complexity of the network can surpass simple models’ capacity for capturing all patterns and finding a thorough solution.

Popular traditional statistical methods include moving averages and linear regression. These are still widely used today, but they need to be applied in combination with other, more powerful AI algorithms.

Figure 2. AI algorithms enhance demand forecasting accuracy.

Bayesian Networks

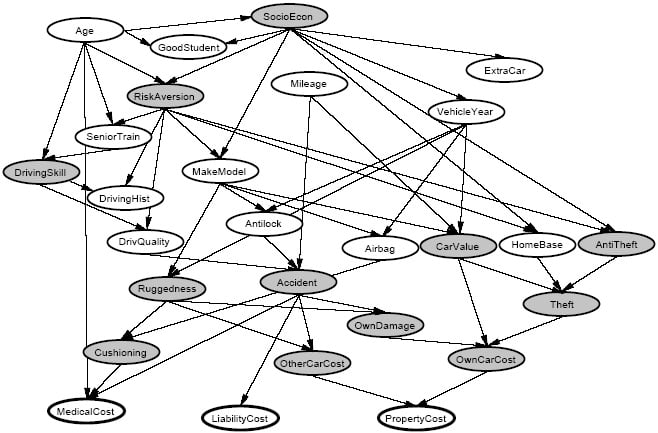

Bayesian networks are another common and widely used probabilistic model. Even though they were invented more than two centuries ago, they have gained renewed relevance thanks to machine learning. Advances in computing power have enabled the processing of larger and more complex networks at faster speeds.

A Bayesian network is an example of a graphical algorithm. It employs what is known as Directed Acyclic Graph (DAG) to represent the probabilistic relationships within a collection of random variables. The network uses these relationships to make inferences on a causal basis. These networks work particularly well when dealing with uncertainty in the data. A portion of this uncertainty is caused by having incomplete data, which is a common scenario in demand forecasting.

Figure 3. A Bayesian network representing factors in the selection of automobile insurance.

Support Vector Machines

Another useful machine learning algorithm discussed in a previous article is the Support Vector Machine (SVM). We have mentioned that demand forecasting is challenging in part due to the wide range of factors that can influence demand. These factors likely have complex interrelationships that traditional linear models struggle to capture. SVM addresses this thanks to its ability to handle both linear and non-linear data well.

Training an SVM model using multi-dimensional information can produce accurate and robust forecasts. The reason this model is considered robust is that it properly weighs outliers, thus reducing the effect of noise on the outcome.

Advanced Algorithm Models

There are other more advanced algorithms, such as Recurrent Neural Networks (RNNs), Gradient Boosting Machines, and time-series types of models.

RNNs are very useful for sequential data analysis, capturing long-term dependencies in the data. For example, they can help make predictions related to seasonality in consumer habits.

Gradient Boosting Machine (GBM) algorithms employ a technique in machine learning called ensemble learning. Ensemble GBMs aggregate predictions from multiple models to achieve better accuracy. They are considered flexible because they can rapidly adapt to complex datasets that include numerical and textual (categorical) data.

Time-series models are another example of a powerful tool that can identify patterns and cyclical behaviors in product demand. There are numerous time-series models, such as ARIMA (Autoregressive Integrated Moving Average) and SARIMA, which is known as Seasonal ARIMA. SARIMA is particularly effective in working with demand that exhibits identifiable seasonal patterns.

Figure 4. AI has tremendous potential throughout every step of warehousing and logistics.

The Warehouse Connection

Thus far, we have covered the supply chain from a high-level point of view, conceptualizing it as a network of multiple connected dots. If we aim a magnifying glass at one of these dots, we will discover that the supply chain network is much more intricate. It is a bit like looking at an atom and discovering all its internal components.

Each dot in the supply chain network could represent a manufacturing facility or a distribution center. Let’s remember that the actual manufacturing step is also part of the supply chain. These facilities may or may not utilize modern automation, but regardless, there is also a lot of potential for AI in these spaces.

In our next article, we will describe how AI improves warehouse management practices and how data generated in these facilities can bring significant benefits when integrated with datasets from the larger supply chain of a business.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: admin@eleok.com