The SLC 500 PLC family dominated automation control for well over thirty years and now, with the recent discontinuation of most of the series, we look at the differences between SLC and modern Logix PLCs.

If you have worked in the automation industry in any facet over the last thirty years, especially in North America, it’s almost guaranteed that you have heard of (or likely even used) Rockwell Automation and Allen-Bradley PLC equipment.

Allen-Bradley PLC Control Systems

Allen-Bradley, a brand of Rockwell Automation, handles most of the hardware manufacturing, while the FactoryTalk brand provides the software that controls the PLCs and other systems.

Over the years, the line of Allen-Bradley PLCs has evolved to an advanced infrastructure capable of controlling entire factories or small independent machines. This article will focus on the differences between the recently-discontinued, yet legendary workhorse, the SLC controller and the more modern Logix family of PLC controllers.

Figure 1. Allen-Bradley SLC systems (left) and ControlLogix systems (right).

History Lesson of Rockwell PLCs

First, a little history. The SLC 500 PLC (commonly referred to as the “Slick 500”) was introduced in 1991. It was designed to be a small-sized PLC that could be scaled as necessary yet still have enough computing power to control large automation projects. The SLC started as a compact, fixed configuration containing the power supply, CPU, and limited I/O, but it later evolved into a flexible rack configuration with the ability to install cards in different slots. The SLC 500 used Rockwell Automation’s RSLogix 500 programming software to program the ladder logic, and RSLinx to configure the communications.

The ControlLogix family was introduced in 1997, offering a similar rack-style configuration, only faster processing and better memory allocation. The ControlLogix product line was geared for larger applications that required bigger ladder logic programs or more complex processes. The programming interfaces use RSLogix 5000 and the newer processors use Studio 5000. The ControlLogix product family is still offered today.

ControlLogix has a smaller relative, the CompactLogix, which uses the same programming platform and many of the same features, but in a smaller, and sometimes slightly more limited capacity for appropriately smaller projects.

Figure 2. A ControlLogix PLC system using rack-mounted I/O.

Hardware Configuring And Communicating

Both the SLC and ControlLogix systems offer a modular approach to processors, communications, and I/O cards. Each rack can contain more than one processor, multiple I/O cards, and a variety of specialty cards such as high-speed counter, motion, and thermocouple cards.

Communicating with the processor to program with an SLC depends on your model. An SLC5/04 requires a special communication protocol called Data Highway Plus (DH+) which uses the RS-485 infrastructure and requires a special programming adapter to connect your laptop. If you have an SLC5/05, you can use the built-in Ethernet port for programming communications. ControlLogix processors today have built-in Ethernet ports for programming and Ethernet/IP communications. If the controller is older, it might not have an Ethernet port but an Ethernet card can be installed in the rack.

Many models in both the SLC and Logix families also make use of serial communication for programming, with an RS-232 or USB port on the CPU.

I/O Capabilities

Because the SLC processors do not support Ethernet/IP natively, you can’t easily connect modern remote I/O devices. The SLC system requires a DeviceNet I/O scanner card to be installed within the rack for communication to remote I/O devices or another supported industrial protocol but not Ethernet/IP.

I/O cards can be added to the rack, and most systems that still use the SLC infrastructure will consist of many I/O cards in large racks. With ControlLogix having multiple options when it comes to I/O, the racks are often much smaller, only containing a processor, network card, and power supply. Most systems use a panel I/O rack or remote I/O blocks for inputs and outputs to the system. Today, most devices come with Ethernet/IP capabilities (or an option for such a protocol) so there is no need for additional communication protocols.

Programming

This aspect is where the two systems most significantly diverge. The SLC 500 models use RSLogix 500 which does allow technicians to program in either ladder logic or structured text (two of the most common PLC programming methods), but how the variables are defined is what differentiates the two systems. RSLogix 500 separates the controller memory into two main categories: data files and program files. Data files represent different types of numeric values and they consist of I/O, statues, bits, timers, counters, integers, floating point, and ASCII. Program files are your subroutines and programs.

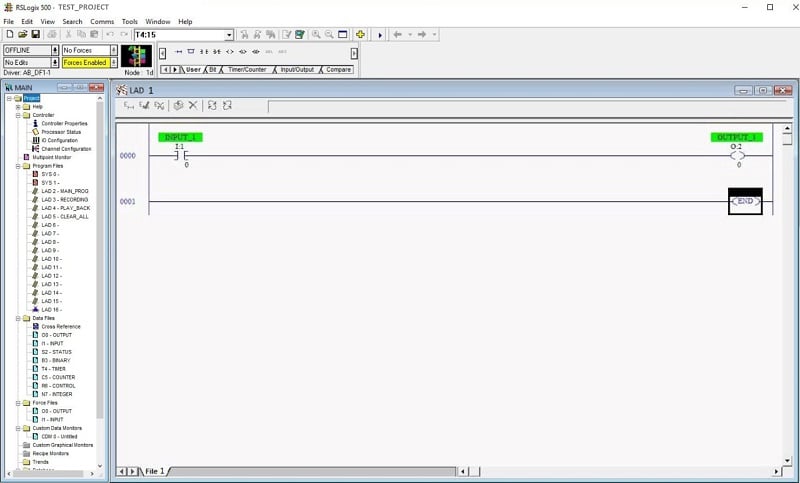

Figure 3. An example of an RSLogix 500 program.

When addressing tags, you must always know what kind of data type the tag will use. For example, say you wanted to seal in a memory bit with some logic, you can’t create a variable called “MemoryBit,” you would need to use one of the pre-defined memory bits which is often addressed as B3:0.0 (although you can assign them logical descriptions). Each processor has a maximum of 16 words of data giving you access to a maximum of 4096 bits. Similar restrictions are applied to all other data files, such as timers (for example, T4:0) or integers (N7:2).

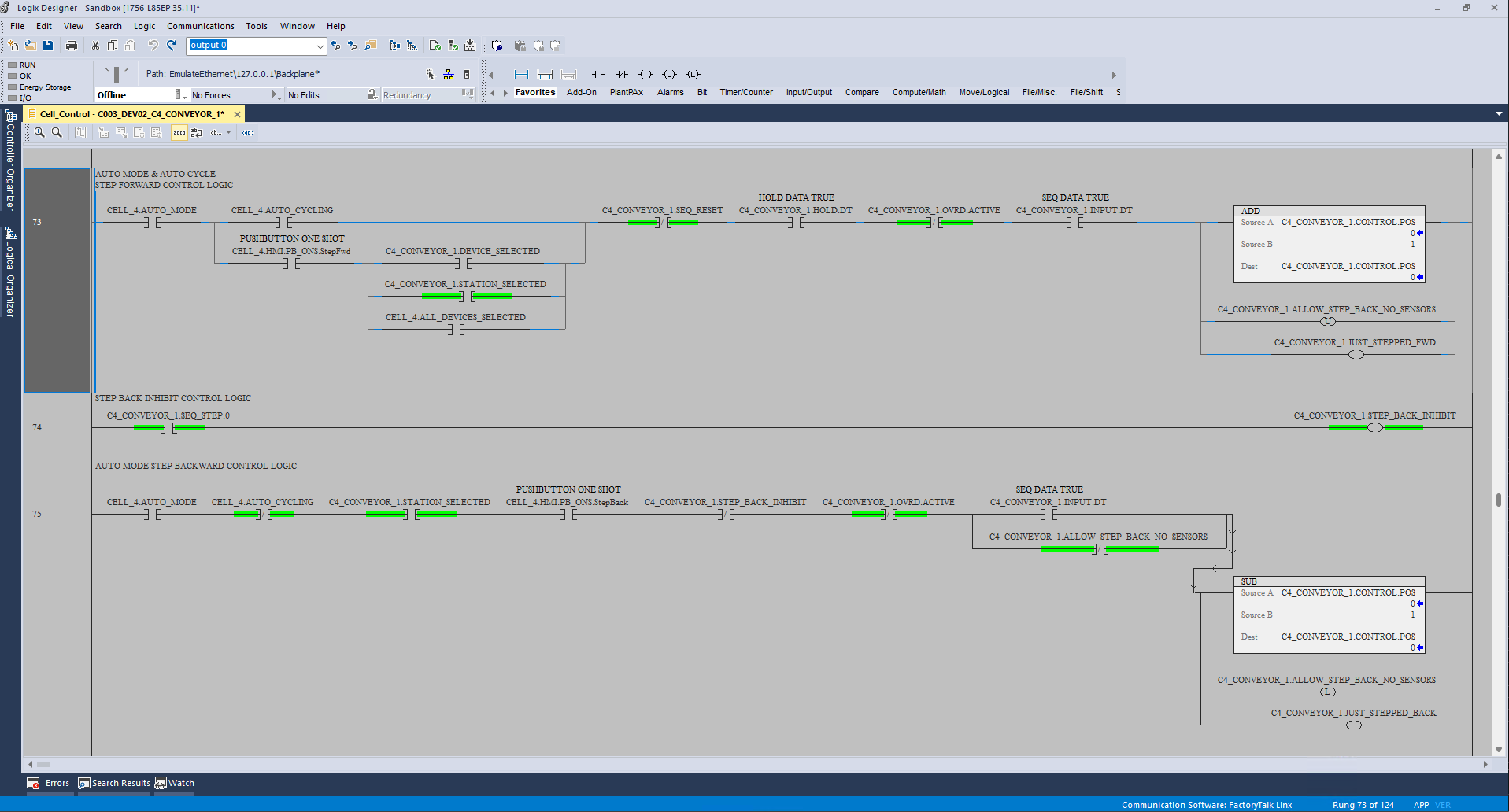

Turning to the ControlLogix hardware, RSLogix 5000, rebranded to Studio 5000 (Logix Designer) as of version 21, is the suite used to program all of the ControlLogix and CompactLogix PLCs.

This software uses tag-based variables, which usually proves to be a more user-friendly approach to tags within a PLC. A user can simply open the tag database and create any number of tags with any kind of data type until the maximum memory of the PLC is reached. These tags can then be used within the logic by simply typing the name of the tag into the editor. A handy feature is the user-defined data type. This is a data type customized by the user and can consist of any combination of standard types. The user-defined structure is given a name and can be used with any tag. This allows users to create more flexible and orgnized code as compared to the SLC method.

Figure 4. Example of ControlLogix and the Studio 5000 programming software.

Out With The Old, In With The New?

So, you’ve been tasked with replacing an SLC5/05 processor with a new ControlLogix PLC; what have you gotten yourself into? This could be quite challenging or fairly simple, it all depends on whether you have the comments for the code or not.

The old SLC processors had very limited memory space, so all of the rung comments or tag comments couldn’t be stored in the PLC. If you were to upload the entire program from the processor, you would lose any comments and trying to determine the exact role of B3:2.6 would require extensive cross-referencing and documentation.

Most of the work will be porting over the logic to the newer system. Rockwell Automation has software tools included with RSLogix 5000 and Studio 5000 that will convert the program for you, some manual validation will be required after the conversion. If your equipment is still using DeviceNet or ControlNet, the new processor will require a communication card installed to continue using those networks.

Figure 5. A SLC 500 PLC system.

Starting With The Old

If, by chance, you have been gifted a SLC processor, or perhaps that’s all you have sitting on the shelf for your new project and you want to give it a go, it will probably work just as reliably as any new system. Don’t forget, many factories ran the SLC processor for many years and there are still many processors in the field today! Here are some tips that might help you be successful.

You will want to make sure you document your code as best as you can. Use spreadsheets to track what data files are being used and give as much context as you can to prevent endless cross-referencing in the future.

Your I/O might be limited to only I/O cards, without access to remote I/O blocks. If this is the case, account for lots of wire runs out to the field. If you can mount your controller as close to the equipment as possible, you might be able to reduce the length of some cable runs.

Most of the SLC processors have been discontinued, but RSLogix 500 software is still available from Rockwell Automation, contact your local Rockwell sales rep to review licensing options. Software can sometimes be the largest cost in a system like this.

The scan time of the SLC processor is considerably slower than the ControlLogix processors so pay attention to how your code is laid out concerning the I/O.

What’s Better, SLC or Logix?

At the end of the day, your process probably doesn’t care if you are using an SLC processor or a new ControlLogix L8 processor, it’s all ladder logic in the end. Thousands of SLC PLCs are running reliably in the field, but the modern capabilities and support usually tempt engineers to adopt the new Logix processors for any upgrade or greenfield operation, and it’s likely that the industry will see a continued migration to this platform over the next few years.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: admin@eleok.com