Learn about the modules and systems that provide a network connection to the outside world, transforming traditional PLCs into true, modern process automation controllers (PAC).

The name PLC is going to stick around for a very long time. No matter what capabilities are contained inside an industrial controller, whether that includes I/O, networking, or even an operating system, it will still be called a programmable logic controller. Signals will still be shared with real-world I/O devices; we simply add new ways to engage with other equipment and the world in general. Call them what we want–PLCs, PACs, IPCs–these are all valid names, but the label of PLC is bound to be hard to overturn.

Bringing advanced communication modules into the mix is the final building block of the modern PLC system, adding to the components we have already discussed: the power supply unit, the CPU, and the I/O connections.

Communication Systems in PLCs

As with many functions inside a PLC these days, we can find communication systems embedded right into the CPU module or install add-on modules to expand the system for greater flexibility.

Programming Interface

In some PLCs, there is an immediate distinction we must make between programming and networking. Sometimes, these are achieved through the same interface port, so there is really no difference. However, a dedicated programming port usually arrives in one of two ways.

A USB port (usually a type B, mini, micro, or type C) is a point-to-point connection used exclusively in PLCs for the downloading and uploading of programs to the host IDE computer. Although extremely simple and reliable, it does require the computer to be physically located within a few feet of the control cabinet if you ever need to edit or monitor the PLC.

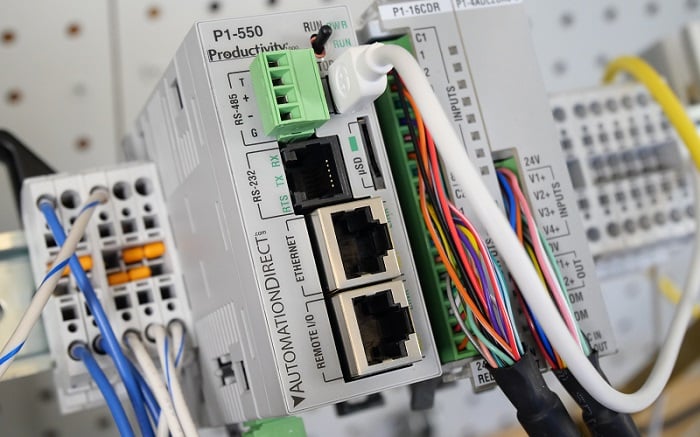

Figure 1. This PLC CPU has a micro USB for programming and numerous other network interfaces.

Alternatively, and often on slightly older equipment, is the 9-pin DB9 serial interface. We cannot immediately assume that this is limited to programming since this port also carries the common RS-232 interface for communication systems like Modbus. However, since this one is also a point-to-point interface, it’s not seen on large networks. A variation of the DB9 connector is a 6-pin RJ11, like a narrow version of a CAT5/6 connector.

Embedded Network Interface

“Embedded” is the term we use when something is built right into the computational unit of the device, in this case, the CPU of the PLC. Most CPU modules have at least one network interface; some have many. Sometimes, it even seems like the designers had a contest to see who could cram the most network ports into the front of the module.

These embedded ports usually include one or more of the following: Ethernet, PROFINET, RS-485, and RS-232. Ethernet and PROFINET appear as the RJ45 plug, common to all familiar Ethernet networks. RS-232, as noted before, may appear as the DB9 connector, simple screw terminals, or it may be fashioned right into a simpler 4-wire harness shared with the RS-485.

Figure 2. Several different serial network port options for RS-232/422/485.

Of these options, RS-232 is the only one designated for a single point-to-point connection. This limits its functionality in networking, but it’s common to find among legacy equipment, so it remains.

The other three network types are multi-drop, meaning they can communicate across many devices, each with a unique address. RS-485 is a bit of an older standard, and it is now commonly used to link across Modbus, PROFIBUS, and other proprietary networks, such as Data Highway (DH485) from Allen-Bradley.

Industrial Ethernet and PROFINET are variations of the original Ethernet standard. Most large companies tend to pick one of the two protocols and stick with it. Still, some PLCs allow for running a controller as a scanner or host with either protocol, sometimes even simultaneously, since the physical port is the same. If your automation process relies on many brands and generations of equipment all talking to the same controller, you’re probably better off selecting the proper modules that can be dedicated to each task.

Modular Network Interface Cards

PLC manufacturers have two different strategies. Either the communications are all lumped into the CPU module, or the CPU is left very basic, and we use add-on cards to support network drops. The second strategy is usually the case when dealing with a large system with more than 2-3 network points.

You can absolutely purchase modules compatible with the previously-mentioned systems, including Ethernet, PROFINET, RS-232, and RS-485, but there are many others. Here are some examples–there are many more:

Figure 3. For this PLC, the CPU is limited to only programming, leaving the networking task to add-on modules as needed.

Fiber Optic

This is usually an Ethernet module with a physical fiber network. You are unlikely to find many CPUs with fiber built right in.

EtherCAT

This protocol, founded by Beckhoff Automation, is a higher-speed variant of Ethernet, specifically for control automation technologies (hence the name CAT). Some controllers do include this as an embedded protocol.

DeviceNet

This network, built from CAN technology, was founded by Allen-Bradley but is now transferred to open-source for wider integration. It uses a flat or round multi-conductor cable.

Figure 4. This DeviceNet module (actually for a field I/O system) uses the round-style cable.

HART

The highway-addressable remote transducer is a digital protocol that rides on a 4-20 mA analog signal, allowing HART devices to be installed into an existing analog system. However, HART does require a dedicated module; a simple analog out module cannot translate the HART protocol.

IO-Link

An increasingly popular protocol allows data and configuration along a normal M12 cable, and simple discrete devices can exist right alongside smart IO-Link devices–a great capability for field-level flexibility.

Many other protocols can be found in modules and embedded in the CPU for specialty applications.

Installing and Configuring a Module

The process is much the same across all models of PLC. Modular cards fit into the chassis or connect with a wiring harness. The IDE always contains a hardware manager that examines the configuration of all modules and embedded networks. These can be scanned or manually added offline.

Figure 5. Installing and commissioning a modular network card includes adding it into the hardware manager and setting the address.

Most networks require an address or node number, which is easily set. After downloading, the network card is running, and it can scan its own network for new devices or have those devices manually added. The exact steps vary by IDE, but this is a very consistent process.

Troubleshooting PLC Communication Systems

Most technicians do not enjoy network troubleshooting, as it’s usually far more difficult than for I/O signals. High-speed data cannot be traced with simple handheld tools, and the applications are far more software-dependant than, say, discrete on/off updates. But as the controllers become more capable of handling many tasks, they must be flexible enough to communicate with a lot of equipment, which means network protocols!

Figure 6. A wide variety of field devices means that every PLC will include different I/O and communication interfaces by necessity.

One recommendation in this area is taking online or in-person classes, both from OEMs and from independent sources, as this can be a great way to learn from professionals who share a similar background to you and understand your pain points, explaining systems in a way that makes you feel comfortable and ready to tackle inevitable future challenges.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: admin@eleok.com