Several use cases for industrial AI get a lot of attention, like maintenance and process optimization. Learn how AI has been used for years to ensure high-quality product monitoring and output.

Maintaining high quality standards has always been a top priority in manufacturing. We have all read news stories about large product recalls affecting all kinds of industries, from food to automobile and technology production. These recalls can be financially devastating for companies and severely damage customer trust and reputation. Even minor defects can have significant repercussions.

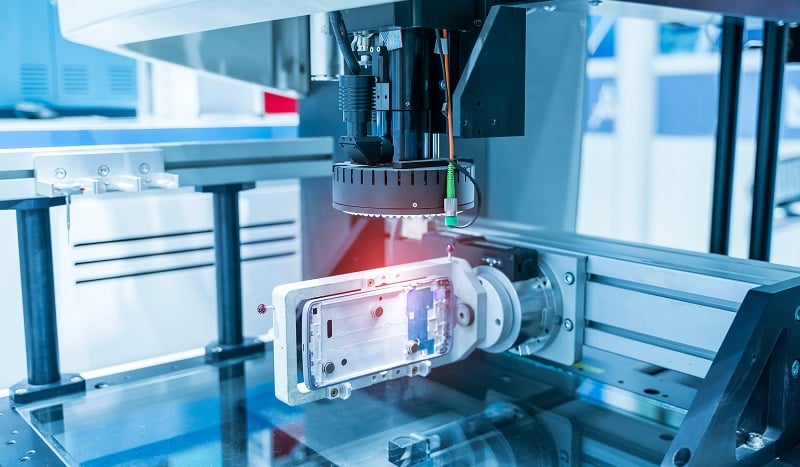

Figure 1. Machine learning, paired with vision and sensing, is revolutionizing predictive maintenance and quality control.

The arrival of artificial intelligence has marked a transformative era in our manufacturing industry. Quality control processes are particularly well-positioned to reap many benefits from this transformation. AI is helping redefine quality assurance processes that have traditionally been human and labor-intensive. In this article, we will talk about AI-enabled strategies and technologies that are revolutionizing quality control.

Real-Time Monitoring

Those traditional quality control methods that rely on labor-intensive manual processes are highly prone to human error. These methods regularly involve post-production inspections, which is more significant. This means that defects can only be detected after the fact. When severe issues are discovered that lead to a product recall, it becomes more expensive the further down the supply chain it is discovered.

One of the most significant advantages of using emergent AI-enabled technologies in quality control is the ability to monitor products and processes in real time. Moreover, instead of relying on random sampling, some kinds of technology can inspect 100% of the product. By doing this, defective products can be kept from traveling further down the production process, thus reducing costs.

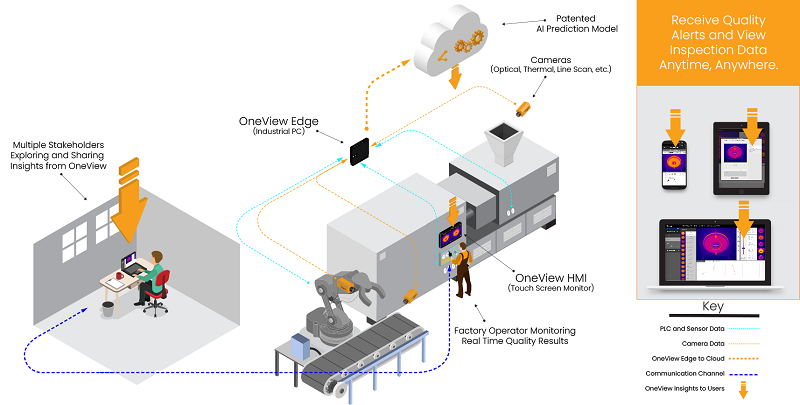

Figure 2. An example of the system architecture of an AI-enabled quality control system.

In an earlier article, we talked about the typical architecture of an AI-based predictive maintenance system. An AI-based QC system consists of the same layers and types of devices. Sensors and cameras help collect process data and relevant metrics from production lines. We also employ edge computing and IoT gateways.

The cloud or server layer can implement many of the same machine learning algorithms as those from predictive maintenance. There are other algorithms, such as those that deal with imagery and computer vision. Just like predictive maintenance, one of the primary goals of leveraging AI algorithms in quality control is the ability to make predictions and classify data.

Computer Vision

Computer vision involves the use of cameras to inspect products visually. Captured imagery is processed and analyzed using advanced algorithms to detect defects in the product or potentially negative trends within the process.

One of the most common types of algorithms employed in vision systems is called Anomaly Detection. Its primary purpose is to detect anomalies or outliers in processes or product appearance. Anomaly detection algorithms can be supervised or unsupervised and are typically trained using datasets with defect-free images. Once the model understands what constitutes a ‘standard’ product, it can be tested using images with defects to calculate the accuracy rate. Anomaly detection using cameras has been around for several decades, and while it may not sound revolutionary, it is still considered one of the first applications of “good old-fashioned” AI.

Figure 3. AI-powered computer vision systems can detect minor defects.

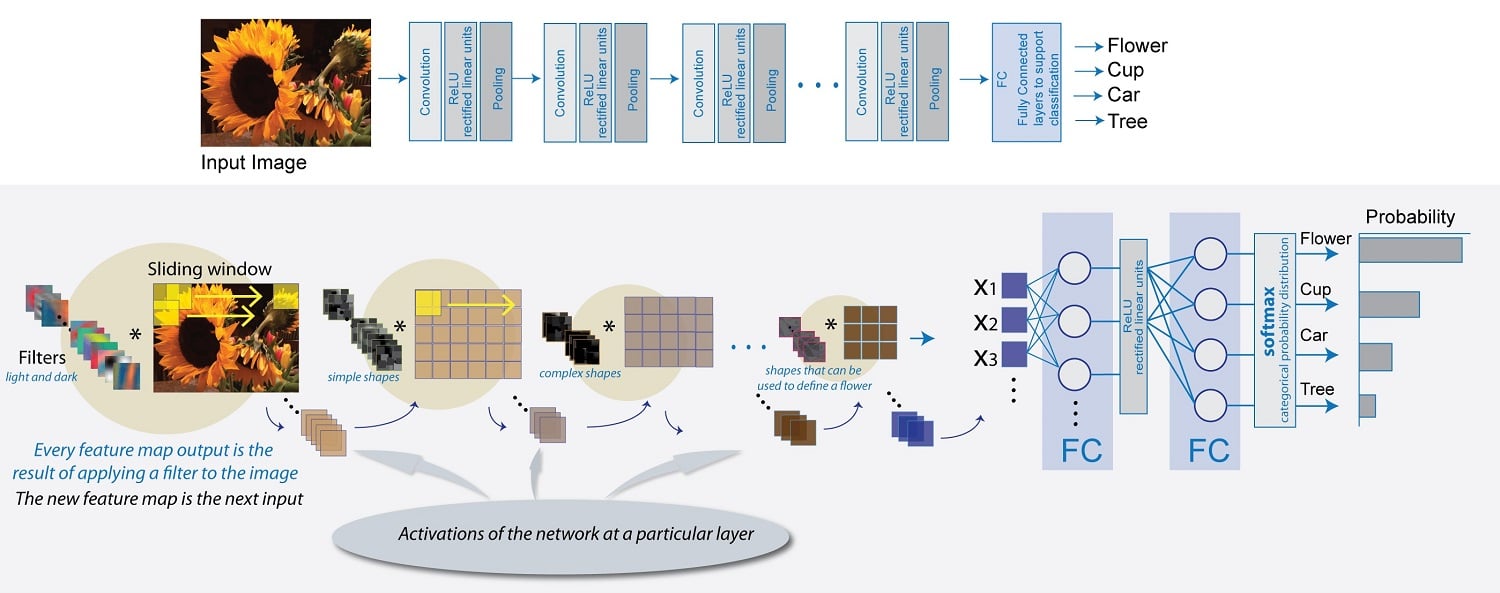

In the modern era, the advent of a field of study called deep learning has produced powerful new algorithms. One of them, which has tremendously boosted the capabilities of vision systems for quality control, is called Convolutional Neural Networks (CNNs). CNNs are now widely used for image classification and recognition tasks. They have enabled technologies such as face recognition and augmented reality. In quality control, CNNs allow cameras to recognize intricate patterns, extract even the most subtle features, and detect minor imperfections in products.

Figure 4. A representation of a CNN analyzing and identifying an image.

Machine Learning for Predictive Quality Control

In our earlier article, we described some of the most common machine learning algorithms used in predictive maintenance. Quality control draws several parallels with predictive maintenance in this aspect. Historized data obtained through sensors, field devices, and vision systems is processed using supervised and unsupervised techniques.

Machine learning algorithms applied to quality processes help predict potential quality issues before they occur. For example, in the pharmaceutical industry, ML can help predict anomalies in the drug formulation process. ML analyzes data about environmental conditions and ingredient quality to anticipate issues that could negatively impact drug safety. Other industries, such as semiconductor manufacturing and automotive, rely on ML to predict defects down the assembly line and to fix them as early as possible.

AI-enabled quality control offers many benefits, but it also comes with some challenges. Implementing a new system or retrofitting an existing one with the necessary technology to capture all the relevant data requires a significant investment. It also implies potential cultural shifts within an organization. It is important to provide substantial training for employees to feel more comfortable and knowledgeable handling such critical processes in a different way.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: admin@eleok.com