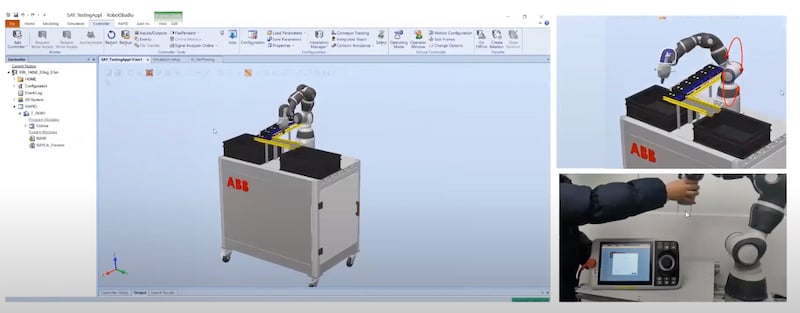

Motion, Vision, and Control: The Whole Automation Package at Beckhoff

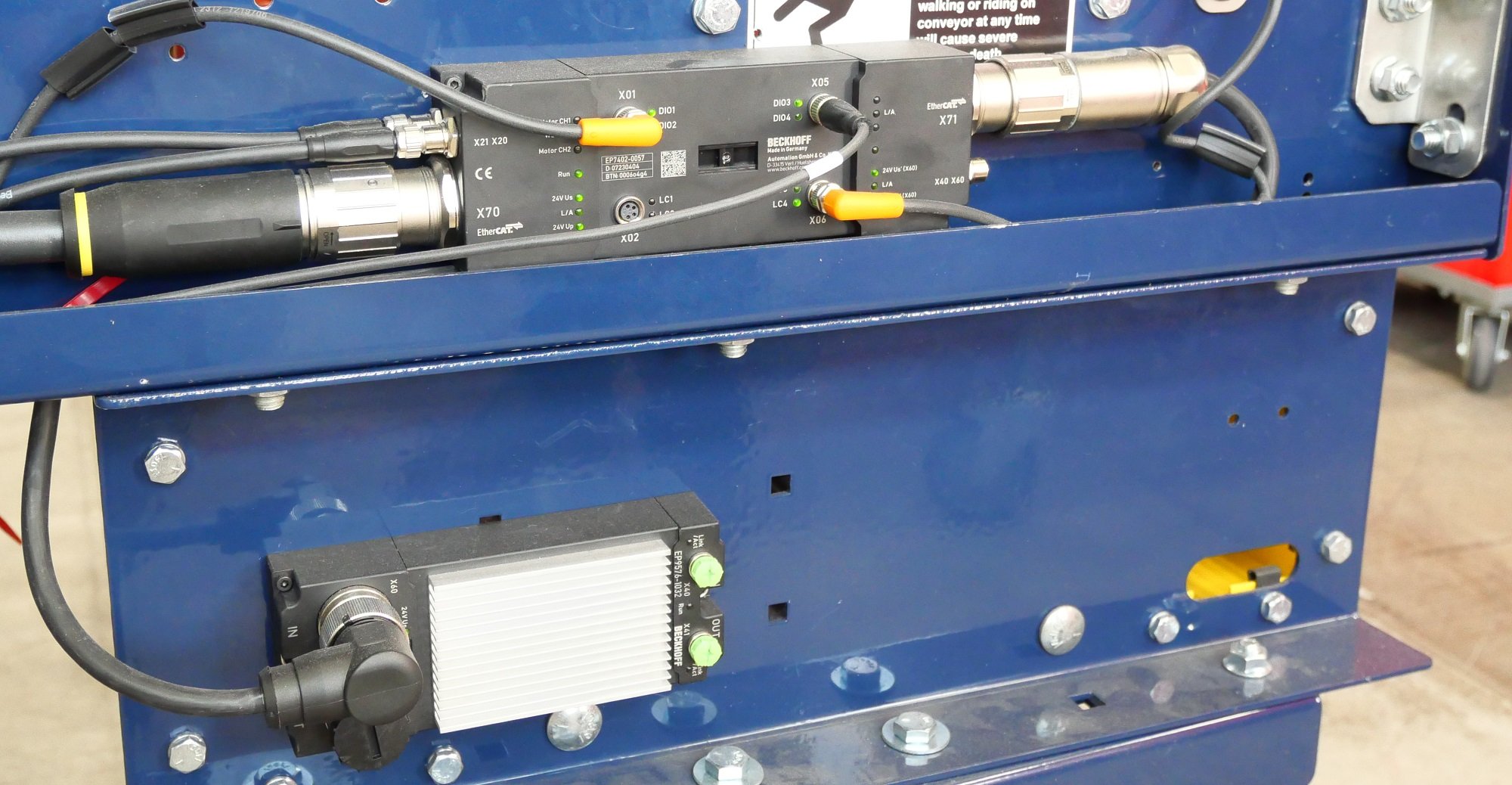

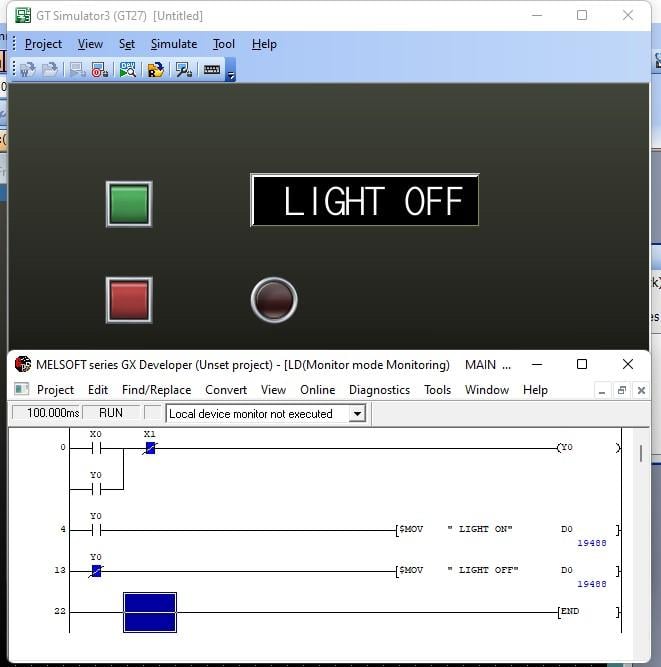

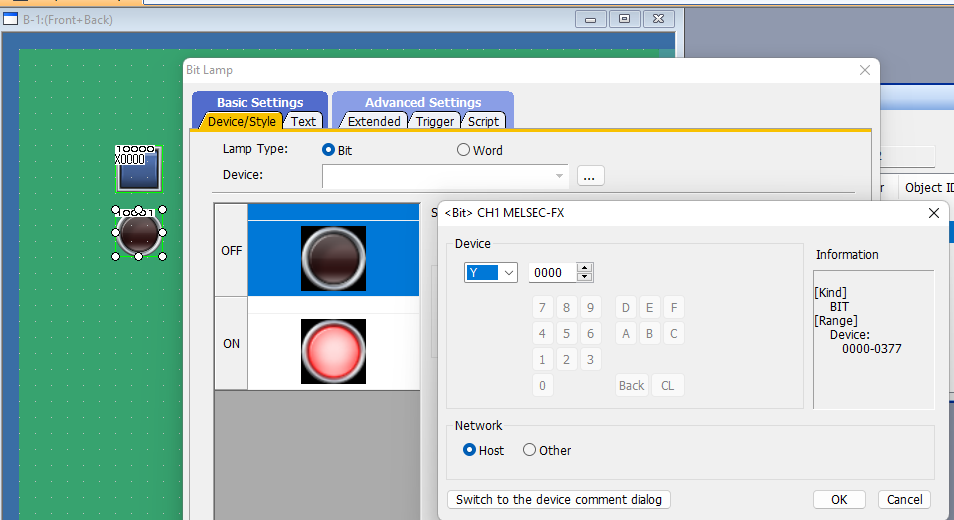

Join Control Automation for a visit to Beckhoff USA in Minneapolis, MN, as we learn about cabinet-free controls, high-speed motion, and magnetic conveyance working to drive the future of the industry. Remember the year 2019? That was one year before COVID rocked the world with shutdowns and global shortages of resources that forced many companies … Read more