This article takes an in-depth look at how magmeters work, the different types of magmeters, and useful equations for calculating flow rates using a magmeter.

An electromagnetic flow meter, often called a “magmeter,” is a device used to measure the flow rate of conductive liquids in a pipe. There are several advantages to magmeters, mostly as a result of their high level of accuracy in combination with a lack of moving parts. Without their lack of moving parts and minimally invasive nature, they can be used for corrosive materials, slow-moving materials, nonhomogenous liquids, and wastewater. The one caveat is that whatever liquid is measured needs to be electrically conductive.

How Do Magnetic Forces Create Senasable Voltage?

All magnetic flowmeters utilize the guiding principle of Faraday’s law of induction, which shows a “quantitative relationship expressing that a changing magnetic field induces a voltage in a circuit.”

This law of induction can be used to measure the velocity of liquids that are conductors, like water, without the need for moving parts. This greatly increases the robustness of flow meter sensors compared to other types of meters.

There are two main types of magnetic flow meters: full bore and immersion. Each one has its own set of pros and cons. But how do they actually work?

How Does a Clamp-on Magnetic Flowmeter Work?

In a magnetic flowmeter, electromagnets are placed either around the outside or inside a pipe. First, we’ll focus on the kind that surrounds the pipe, often called clamp-on, non-invasive, or full-bore magnetic flow meters. Unlike insertion flow meters, they measure the entire cross section of the pipe, providing a higher level of accuracy.

Figure 1. Full-bore magmeters are designed to measure a pipe’s entire cross sectional area.

Full-bore magnetic flow meters use external electromagnetic coils to generate a magnetic field around the pipe, allowing for flow measurement without direct contact with the fluid. This design is beneficial for applications where traditional in-line magmeters may not be feasible or where minimizing fluid contact is desired. They are commonly used in water treatment, chemical processing, and food and beverage industries.

A flowmeter consists of electromagnets surrounding a non-conductive pipe segment, generating a magnetic field perpendicular to the flow direction of the fluid moving through the pipe.

In addition, sensing electrodes then measure the induced voltage generated by the flowing fluid.

The final piece consists of a nonconductive flow tube that is necessary to create the proper conditions for accurate flow measurement.

The process for magnetic flow measurement is as follows:

- A magnetic field is generated across the flow tube by the electromagnets.

- As a conductive fluid moves through the tube, it cuts across the magnetic field lines, separating the charged particles and inducing a voltage.

- The electrodes pick up this induced voltage, which is directly related to the flow velocity of the fluid.

The induced voltage created by the fluid can then be converted into a flow rate reading using a calibration curve, usually provided by the manufacturer to suit individual flow meters. (See equations below)

How Does a Magnetic Immersion Flowmeter Work?

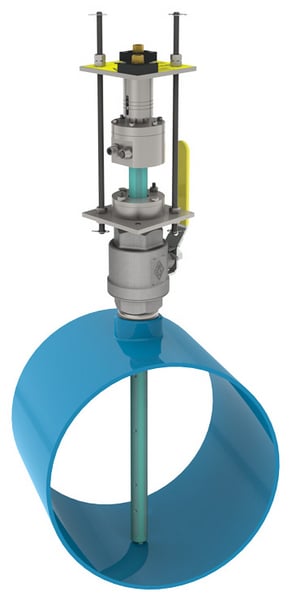

Immersion flow meters differ from full-bore flow meters because they require insertion into the pipe for accurate measurement. They are often cheaper and require less space than full-bore type meters, meaning they can be installed in locations where a full-bore may be difficult to fit.

Insertion magnetic flow meters can be installed with minimal invasion to the system and offer the capability of maintenance and probe removal without the need for system shut down.

Figure 2. Insertion-type mag meters only measure a portion of a pipe’s cross sectional area.

The same guiding principle is used for insertion-type flow meters and the same flow equations apply which also apply to full-bore sensors. The difference between the two is that insertion meters only measure a certain portion of the cross sectional area of the pipe. The probe consists of electrodes on opposite ends of the sensing part of the device. These electrodes create a magnetic field between them that can then be used to measure flow using the guiding principles.

For installation in plastic pipes, the flow meters will often need grounding rings or probes to be inserted into the pipe. This ensures that the meters can achieve proper grounding for accurately measuring the liquid. In order to be removed from the pipe while the system is still running, an isolation or bypass valve can be used to keep the pressurized liquid in the pipe while the flow meter is removed for periodic inspection. Insertion-type flow meters do require some maintenance since they are in contact with the medium flowing through the pipe, whereas full-bore models have quite a long service life.

Useful Equations for Flowrate

The fundamental equation for a magnetic flow meter is derived from Faraday’s law of electromagnetic induction. It can be expressed as:

$$V=k \cdot B \cdot D \cdot v$$

Where:

\(V = Induced Voltage\)

\(k = Calibration Constant\)

\(B = Magnetic Field Strength\)

\(D = Pipe Diameter, Distance Between Electrodes\)

\(v = Fluid Flow Velocity\)

Once the fluid velocity is calculated from the measured voltage, the flow rate Q can be found using the equation:

$$Q=A \cdot v$$

Or, alternatively, using the pipe diameter to determine A:

$$Q=\frac{\pi D^2}{4} \cdot v$$

Combining these relationships allows for determining flow rate based on the induced voltage measured by the electrodes. The calibration constant k is essential for converting the measured voltage into an accurate flow rate.

Measuring Flowrate with Magmeters

Magnetic flow meters all work on the principles outlined in Faraday’s Law, regardless of their construction type. Different types of magnetic flow meters are useful for different scenarios depending on the needs of the application. Clamp-on or full-bore type mag meters are the least invasive type of mag meter, and immersion-type mag meters are often used in areas where it is hard to fit a full-bore meter, or the additional cost of one is prohibitive. Full-bore meters measure the entire cross sectional area of the pipe and insertion meters are only able to measure flow in a portion of the pipe’s cross sectional area.

Regardless of type, electromagnetic flow meters are beneficial to many industries and can provide users with a low-maintenance way to measure conductive liquid flow rates.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: admin@eleok.com