Predicting when maintenance should occur isn’t simply a matter of getting on board with the latest trend, it can save many thousands of dollars in lost downtime and unnecessary parts and labor.

The primary goal of a predictive maintenance system is to minimize downtime by forecasting the health of machines and industrial systems. To achieve this, predictive maintenance relies on a combination of hardware and software technologies to gather and process the necessary data. In recent years, Artificial Intelligence has become a fundamental component of these systems, significantly enhancing their capabilities.

This article takes a deep dive into the crucial role that AI plays in predictive maintenance systems before we explore some of the algorithms that drive machine learning in following articles.

From Reactive to Proactive Maintenance

Predictive maintenance is one of several key strategies employed within industrial maintenance. The other two primary approaches are corrective and preventive maintenance.

Corrective maintenance is the most reactive and only kicks into action after something has already gone wrong. This approach usually leads to more significant disruptions and higher costs.

Preventive maintenance relies on plans and scheduled tasks to address common potential issues before they become major problems. These practices can still lead to higher costs because not every service and replacement will actually be required.

Predictive maintenance relies heavily on data analytics to estimate the likelihood of potential failures for specific machine running conditions and provides according actions. An effective predictive system must capture data points and samples from all the relevant process variables. In most real-world applications, this means that additional sensors and devices need to be integrated with the existing machine or system.

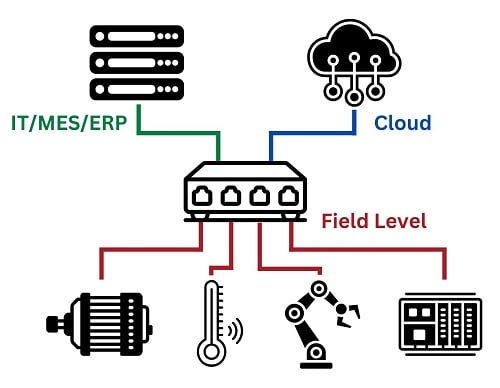

Figure 1. Predictive maintenance relies on state-of-the-art technologies.

Sometimes, these embedded devices come with out-of-the-box AI capabilities. This is quite noticeable, for example, on many modern advanced cameras and vision systems. However, in the case of wide-scale data analytics, the preprocessing, feature engineering, and application of the AI algorithms all happen in a centralized location where the data is concentrated.

In the next section, we take a more in-depth look at the typical components that comprise a predictive maintenance solution.

Components of a Predictive Maintenance System

A modern and effective Predictive Maintenance solution requires comprehensive real-time data collection and accurate AI-driven analytics. To achieve this, several layers of hardware and software are needed.

- Sensor/Field Device Layer

These are the devices that tap directly into the source of the information we need. Some of the most common sensors employed in predictive maintenance are vibration, temperature, pressure, and current.

- Edge Computing Layer

Edge computers are devices that perform some initial processing of the raw data obtained from the previous layer. This initial processing is done as close as possible to the source of the data in order to reduce bandwidth usage through a network.

- IoT Gateway Layer

These gateways receive data from edge processors and field devices, encrypt it, and forward it to a centralized server or the cloud, depending on the design preference.

Figure 2. The main components of a predictive maintenance system.

- Cloud/Server Layer

This is the realm of AI. Cloud or on-premise servers can store data in either its raw form (simple numeric lists) or processed form (tabulated and sorted into data sets) for analysis and recording. Databases are compiled and coalesced to form data warehouses. Once the data has made it all the way to this point, it is ready for AI-based algorithms to take over.

AI-Driven Predictions

Machine learning (ML) is a fundamental discipline in the field of artificial intelligence. It enables systems to ‘learn from’ and make predictions based on data. Machine learning employs algorithms to create statistical models and output these predictions.

An ML solution can look as simple as a Python script that ingests data and applies algorithms to general a result. Now, this is a bit of an oversimplification, but it helps begin to look at AI from a tangible perspective.

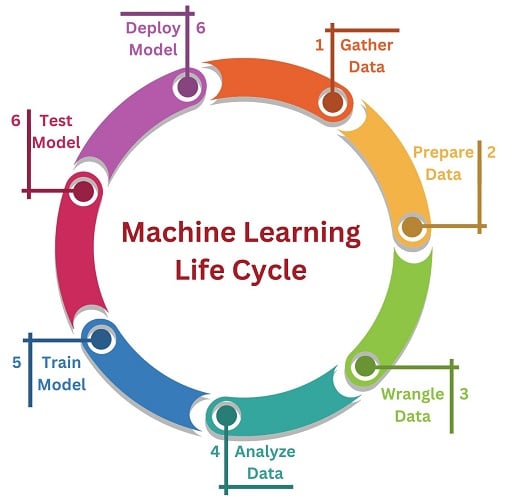

Machine learning is also a cyclical process, or a continuous improvement process, if you will. The machine learning life cycle consists of seven major steps: Gathering Data (selection and ingestion), Data Preparation (exploration and pre-processing), Data Wrangling (cleanup), Data Analysis (algorithm selection), Model Training, Model Testing, and Deployment.

Figure 3. The Machine Learning Life Cycle is a cyclical process.

Now, let’s connect the dots together. The previous two sections of this article have described how predictive maintenance requires data in order to make predictions and have provided an overview of the system architecture you would need to implement in order to gather that data. We are at step number one of the ML Life Cycle.

We hope this helps to paint a picture of how important the first step is. Machine learning, and therefore artificial intelligence in general, needs large amounts of relevant data points in order to give accurate predictions. What exactly constitutes a “large amount” of data? The answer to this will depend on the size and the complexity of your machine or system. The more variables upon which your process depends, the higher the complexity of your dataset. Wouldn’t it be easier to just include all the process variables you already measure? This is possible, but not advisable. Machine learning employs algorithms whose computing cost can grow exponentially when too many variables are used. It is important to select relevant variables for the algorithm. In other words, select only those variables that have an impact on the prediction outcome.

AI Maintenance Predictions

And what exactly is a ‘prediction’ in this application? A prediction in maintenance can take several forms. It can be a recommendation to a technician that a task needs to be performed sooner than expected (or perhaps could be delayed without concern). It can be an automatic recalibration, where the ML application automatically adjusts parameters based on trends. It can be a process input that feeds a set point into another machine.

So far, we have begun to grasp AI in predictive maintenance. We wanted to make these concepts more concrete by providing an overview of their architecture and what role each one plays in a complete solution. Next, we will examine several of the most common algorithms used in designing predictive maintenance analytical programs.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: admin@eleok.com