Protection against faults is crucial for any electrical system. This article examines various protective devices, highlighting their roles and best use cases to ensure system integrity and longevity.

Overcurrent conditions from short circuits, power surges, and other anomalies can cause damage to sensitive components, leading to costly repairs and downtime. The absence of proper protective devices escalates the risk of extending that overcurrent for a long duration, almost certainly leading to catastrophic system failures: fires, control device failure, and harm to operators. Various protective devices are used to mitigate these risks, each with unique features and applications that suit them well for installation under different conditions.

This article delves into the different methods of protecting electronic and electrical equipment from damage, including traditional fuses, innovative electronic resettable fuses, circuit breakers, metal oxide varistors (MOVs), surge protectors, line filters, and line reactors.

Understanding the distinct roles and optimal use cases of these devices is crucial for ensuring the reliability of modern electrical systems.

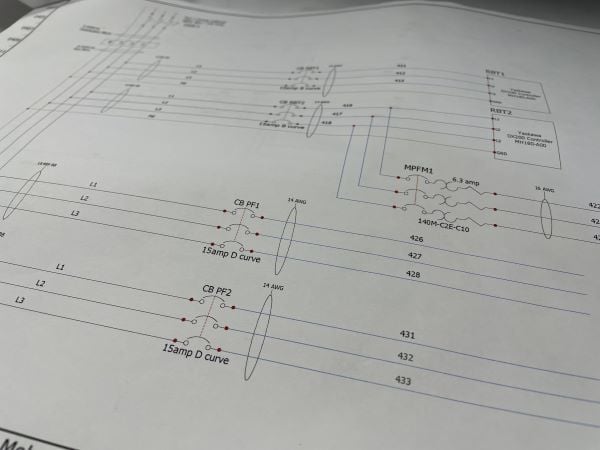

Figure 1. An electrical drawing showcases some of the components discussed throughout the article, namely manual and overload circuit breakers.

Fuses

Traditional fuses are perhaps the most fundamental and widely used overcurrent protection devices. They function by melting a metal wire inside them when excessive current flows through, breaking the circuit and preventing further current flow. They are used in consumer electronics, automotive circuits, industrial equipment, and residential wiring.

The low cost and simplicity of traditional fuses are among their main advantages. They have no moving parts, making them straightforward to install. However, fuses are single-use devices that must be replaced after they blow, leading to potential maintenance issues and downtime. This frequent replacement can be irritating, especially in hard-to-reach areas or critical systems requiring continuous operation.

Resettable Fuses

For those who like the advantages of the fuses but don’t like the idea of one-time use, there is also an electrical component called the resettable PPTC fuse (polymeric positive temperature coefficient fuse).

When excessive current flows through the PPTC, high temperatures cause the polymer to change from crystalline to amorphous, and this expansion breaks the most conductive path, increasing the device’s resistance. This increased resistance limits the current flow and protects the device. The difference in the PPTC fuse is once the fault is cleared (or power is switched off), the polymer cools down, and the PPTC gradually returns to its original state.

Circuit Breakers

A circuit breaker is a switchable protective device used to safeguard electrical power systems by interrupting the flow of electricity under magnetic or thermal conditions. It functions through a mechanism that disengages two normally closed contacts upon detecting a fault.

Circuit breakers are the preferred choice compared to fuses in situations where swift restoration is crucial. This preference is due to their ability to be easily reset and reused multiple times, which reduces the need for frequent maintenance. Installation is dictated under various national and local electrical codes and guidelines. Breakers are applied to different scenarios including motors with various loading factors, so there are different curves available that determine the trip current and speed.

Figure 2. This electrical cabinet also showcases some of the components discussed in the article.

MOVs

An MOV, or metal oxide varistor, is a small electrical component that protects devices from sudden spikes in voltage. Inside the MOV are many tiny diode-like junctions between the zinc oxide grains. A diode limits electricity to only flow in one direction. When voltage is operating at average capacity, the MOV has a high resistance, not letting too much current through, therefore not affecting the circuit much. During high-voltage situations, the MOV’s resistance drops significantly. This allows the current to rush through the MOV instead of damaging the connected devices. So, an MOV’s resistance is dependent on the voltage applied.

A disadvantage of an MOV is it will wear out from absorbing frequent high-voltage spikes, needing occasional replacement. It dissipates absorbed energy as heat, causing deterioration.

Figure 3. A variety of MOV device packages.

In summary, metal oxide varistors (MOVs) are best used for safeguarding against short, high-voltage spikes. On the other hand, fuses and circuit breakers are better suited for offering protection against overcurrent situations. It’s worth noting that MOVs are frequently used in parallel with fuses to protect circuits fully.

Surge Protectors

Surge protectors are used in electrical circuits to shield equipment from power surges that cause excessive voltage. They achieve this using either MOVs or gas discharge arrestors (GDRs). These components work by limiting the voltage through their ability to become more or less conductive or diverting excess voltage to the ground.

Pairing a surge protector with a fuse or circuit breaker is advisable for optimal protection in a typical electrical circuit. While fuses and circuit breakers protect against overcurrent situations, surge protectors specifically safeguard against overvoltage events. Together, they provide comprehensive protection for your electrical devices.

EMI Damage

Electrical noise, or electro-magnetic interference, is another type of condition that can lead to overcurrent and damage in circuits. More often, this problem affects digital and analog communication, but certain harmonics can lead to a rise in current, heat dissipation, and eventually device failure.

Line Filters

If you have a TV along with other electronic devices in your home, they can produce “electrical noise” that interferes with the signals and proper functioning of your TV and other equipment. This noise is similar to static or interference, making it difficult to hear your favorite song on the radio. Line filters (EMI Filters) are commonly used to combat this problem. The EMI filter is a unique barrier that blocks unwanted noise from entering your devices and prevents the noise generated by your devices from causing other issues.

Modern electronic devices, such as power supplies, inverters, and rectifiers, often use high-frequency switching techniques to convert power efficiently. However, these fast-switching actions can create noise, a type of electrical interference. An EMI filter uses a combination of inductors and capacitors to block or reduce unwanted high-frequency signals, allowing only the desired frequencies to pass through. This helps in two directions: it prevents the noise generated by your devices from traveling back into the power grid, and it also stops any existing noise on the power grid from entering your devices.

Figure 4. An example of a line reactor device.

Line Reactors

A line reactor is a device that limits current rise, reduces spikes and surges, and minimizes electrical noise. Line reactors are commonly found in VFDs (variable frequency drives).

When electrical current flows through a line reactor, it generates a magnetic field that resists changes in the current. A coil of wire creates the magnetic field. This resistance helps to smooth out fluctuations and reduce noise, making the power supply more stable. Using both a line reactor and a line filter can be beneficial.

Using both a line reactor and a line filter can enhance protection by addressing a wider range of electrical issues, such as smoothing out current spikes and blocking high-frequency noise.

Current Protection

The combination of devices available for both the massive, instantaneous faults as well as the more gradual and annoying (yet still dangerous) power fluctuations can help to ensure smoother and cleaner power, improving the performance and lifespan of your equipment.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: admin@eleok.com