Designing, installing, and maintaining control systems involves a lot of wires. Each wire has a purpose, often indicated by the color of the insulation. But what are the common colors, and what do they mean?

Riggs: Well, I’m cutting the red wire, okay?

Murtaugh: What? What? A minute ago you said blue.

Riggs: Did l say blue?

Murtaugh: Riggs, you said blue.

Riggs: Well, l meant red.

Murtaugh: You sure?

Riggs: We can do it your way if you’d like.

– Lethal Weapon 3 Script

The opening scene of Lethal Weapon 3 features Riggs and Murtaugh, two police detectives, attempting to defuse a bomb. They are confronted with the typical Hollywood question involving which wire to cut. For the purposes of the movie, the assumption was that the color of wire insulation was somehow magical or that the bombmaker was kind enough to reference standards to build his bomb.

Wiring Standards in the US and International

The National Electric Code (NEC) specifies standards for all things electricity for residential, commercial, and industrial building projects. It gets updated every three years for such purposes as adding content for electric vehicle charging stations or clarifying language on grounding electrodes. However, the NEC only specifies a few conductor insulation color codes. Instead, the NEC focuses more on how wiring is to be performed: what gauge of wire is required, what types of raceways and conduits should be used, how to support wiring and wire coverings, and how receptacles, branch circuits, luminaries (lights) and protective devices are to be wired.

Besides NEC, there is the International Electromechanical Commission (IEC), which also provides a set of standards. These standards are used throughout most of Europe and other parts of the world and are generally in accordance with the NEC. IEC 60445 provides guidelines for color coding wires and devices.

The NEC speaks of the Authority Having Jurisdiction (AHJ), meaning any local, city, county, or state authority has the final say in how wiring is to be performed. In general, these are more strict than the NEC and may specify a color coding system for wiring.

Finally, there are informal standards that may suggest or permit certain wire insulation colors. These conventions may be required by a particular employer but are not legally recognized. For the sake of consistency, it may be that a new housing development will use a certain color to indicate all travel wires for three-way and four-way switches across all of their newly constructed homes. This is just for ease of troubleshooting and not legally binding.

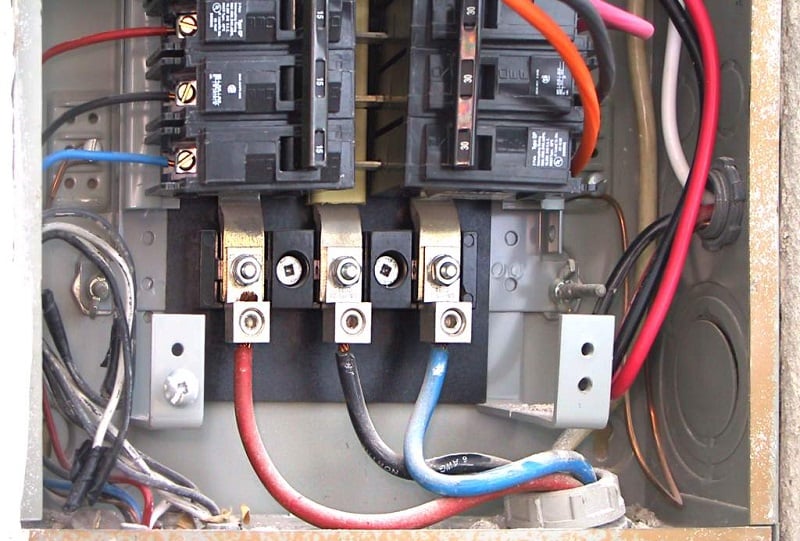

Figure 1. While the NEC does not explicitly specify wiring colors, industry standards designate red, black, and blue for 208 V / 120 V.

Conductor Purposes

The Lethal Weapon actors were not aware that any of those wires could conduct current in the same manner as the others, regardless of insulation color. The ordinance designers in this movie probably did not consult the NEC or IEC or gain the permission of any AHJs or their employer conventions since they were not interested in preventing shocks, fires, or making it easy to troubleshoot. In the real world, however, it is important to abide by legal standards and conventional wisdom when designing and installing electrical systems.

All About Circuits outlines the wiring color code standards and conventions, showing how different parts of the world incorporate colors for single-phase, three-phase, and direct current (DC) systems. It is worth noting that some of these colors have changed, so the age of a building and its wiring can play a part in troubleshooting procedures, as the color conventions may have changed since its original construction.

Direct Current (DC) Wires

Direct current wires, such as those found in automotive wiring, typically use red wires for a positive voltage and black wires for a negative voltage. From there, either a black or green wire bonds the negative terminal of the battery to the car’s frame as a ground.

For industrial applications built to UL508A specifications, this guideline for industrial control panels suggests colors for the positive (+) and negative (-) 24 V DC signals. In these cases, including PLC input and output conductors, all (+) 24 V wires should be blue, and all (-) 24 V wires should be white with a blue stripe.

Some European color conventions (commonly found on NPN and PNP 3-wire devices from all suppliers, EU or Int’l) use brown for (+) DC connections and blue for (-) DC connections.

Following this example of two opposing guidelines for various circumstances, it can be seen that subtle differences in the voltage level, application, and the country of origin may dictate conductor insulation colors. The overall answer? Learn to use your voltmeter and NEVER assume a voltage based on a wire color alone.

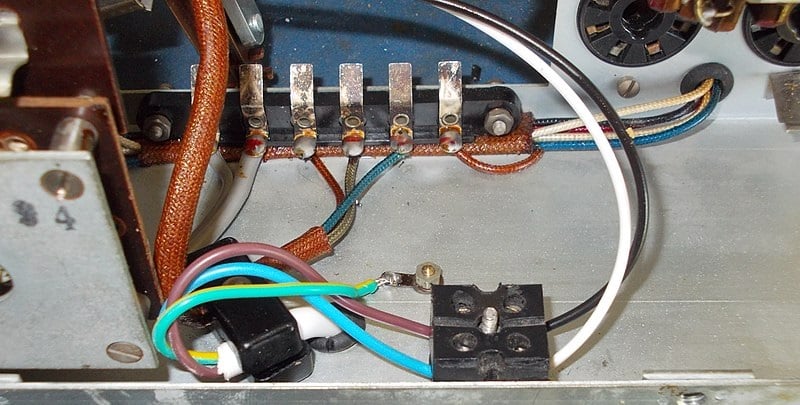

Figure 2. In this installation, the blue and the green (with yellow stripes) are very similar in color. The green wire is used for a chassis ground.

Ground Wires

Green insulation indicates ground wires. Think “Green-Grass-Ground”. However, green insulation is not the only way to determine a ground wire. According to the NEC, green insulation with a yellow stripe is also an indication of ground. Either of these is acceptable, and there is no real difference between them. Both of these colors are to be used explicitly for ground connections.

Bare metal conductors (copper, copper-clad aluminum, aluminum) can be used as a ground. In fact, bare metal conductors should ONLY be used as a ground. If they were used for conducting current during normal operation, they would be very unsafe and risk shock. Aluminum and copper-clad aluminum cannot be used where they are in contact with concrete or masonry due to corrosion issues. These requirements are reiterated throughout NEC Articles 200-250 in various contexts.

Ground wires are not to be confused with neutral wires, present in single-phase and three-phase AC systems. These neutral wires have white or gray jacket colors.

Alternating Current (AC) Wires

Depending on the industry and application, there are many voltage levels, from 24 V up to many hundreds and even thousands of volts. As with the DC wires, there are competing standards and guidelines, so it should be clearly stated that the jacket color sound NOT be a clear indication of function. Skepticism is a great safety tool when it comes to wiring.

For the most part, in the US and Canada, 120 V 1-phase AC systems use black for the line wire (L1) and white or gray for the neutral (N). In a 240 V system with a second line wire (L2) uses a red wire. In Europe, the convention is similar to DC, with L1 being brown and L2 (or N) being blue.

Figure 3. Caution is important: blue wires could mean DC or AC voltage, and the same for red wire colors.

3-phase systems vary with geographical location and voltage level, so it is wise to rely on current local guidelines before maintaining and installing them. Any personnel with permission to access 3-phase locations should be knowledgeable about the equipment and the guidelines before proceeding.

Wire Color Code Pitfalls

Color coding of wires, while popular, does have its pitfalls. The two largest pitfalls are that the wires can change color with age and that folks who experience color blindness have difficulty determining the insulation color.

Theoretically, high-quality insulated wire will not change color. If kept within tolerances as outlined by the code, the insulation will not be exposed to high enough temperatures to thermally degrade the color, and it will be made with dyes that do not fade with time. However, the reality is that wires become dusty, faded, or otherwise discolored. Any darkened spots indicate that the wire was exposed to high temperatures and should be replaced.

Color blindness strikes many people, and some may not even realize they are colorblind until they are faced with a question like, “is this brown or red?” Red-brown and blue-green color blindnesses are common, as are several other varieties. If either the installer or the electrician servicing the line experience color blindness, dangerous misunderstandings can occur. Because of this, wire insulation color should not be relied on as the only method of testing a wire’s origins and meaning.

Cautions to Electrical Technicians

The NEC only specifies a few mandatory color codes. The IEC suggests others, and likely the AHJ and certain conventions may specify a few more. However, when performing a repair, engineers and technicians should not simply rely on the color of the insulation alone.

Tracing wires, using a multimeter, or other such methods can be used to verify wires are connected as expected. Even though the NEC does not say much about color coding, it is essential for showing electricians how to properly size conductors, calculate load requirements, choose proper fittings and conduit, and many other important considerations.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: admin@eleok.com