What is a PLC? This article will lay out a succinct definition of a programmable logic controller and explain its basic components.

The programmable logic controller, or PLC, is ubiquitous in every kind of process and manufacturing industry today. PLCs were initially designed to replace electromechanical relay systems in order to offer a simpler solution for modifying the operation of a control system. Rather than having to rewire a large bank of relays, a quick download from a PC or programming device enables changes to the control logic in a matter of seconds.

In this article, we’ll introduce the concept of a PLC and explain its basics.

What Is a PLC?

A PLC is an industrial-grade digital computer designed to perform control functions—especially for industrial applications.

The majority of PLCs today are modular, allowing the user to add an assortment of functionality including discrete and analog inputs and outputs, PID control, position control, motor control, serial communication, and high-speed networking. Compared to older technologies such as relay banks, the PLC is far easier to troubleshoot and maintain, more reliable, more cost-effective, and far more versatile.

Figure 1. A modern set of industrial PLCs. Image used courtesy of Siemens

Modicon, shortened from ‘modular digital controller’, is both the name of the first PLC product invented in 1968 and the brand that invented it, although now owned by Schneider Electric.

While it may not look like a typical household computer, the core of a PLC is the very same technology seen in the computers and smart devices most people use in their everyday life.

Basic Components

A PLC is composed of a few basic parts. They might look slightly different from various manufacturers, but the purpose and scope of each component are the same. These include a power supply, a central processing unit (CPU), input/output cards, and a backplane or rack that the input/output (I/O) cards are placed into.

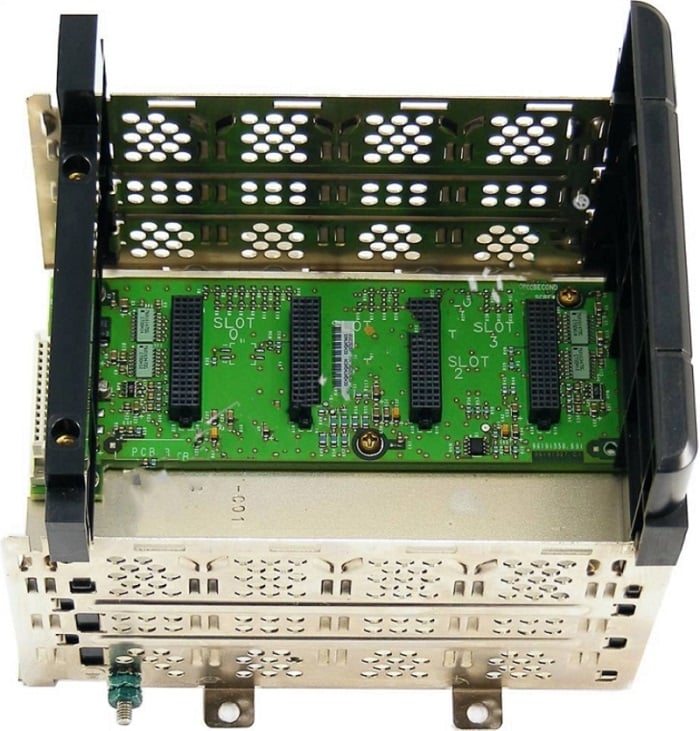

The backplane, as shown in Figure 2, creates an electrical connection between all the separate components, giving the PLC its modular design. This electrical connection includes both power and communication signals. Many PLC manufacturers use proprietary communication protocols on the backplane so that I/O can securely talk to the CPU.

Figure 2. Rockwell ControlLogix backplane. Image courtesy of Rockwell

The Power Supply

The power supply accepts either 120VAC or 24VDC depending on the application and the circumstances of the installation. As mentioned above, this voltage is bussed down the backplane providing power for the CPU and I/O modules, which come in the form of “cards”. These cards can quickly be added or removed from their slot in the carrier.

It is important to note that the power supply for the CPU does not provide power to the field devices, such as sensors and coils. This power supply connection must be established to the cards separately.

Central Processing Unit (CPU)

The CPU is the actual ‘brain’ of the PLC, making it a computer. Even small, non-modular PLCs contain a CPU. Input signals come from the I/O cards, and the logic programs make decisions based on the signals. If required, the CPU then commands outputs to turn on and off as signals and conditions change.

Programs may include advanced functions such as math operations, timing, counting, and sharing information via modern network protocols. Many of these operations were extremely difficult, if not impossible, with the older relay systems.

I/O Cards

Sensors, buttons, switches, relays, solenoids, and even networked devices share information with I/O signals connected to screw terminals on the I/O cards. These cards can be chosen based on the needs of each machine and facility. In some small PLCs, the I/O terminals are not modular cards, but rather are conveniently installed right on the side of the PLC.

Due to the wide variety of I/O device construction, there are a wide variety of discrete and analog modules, with terms such as ‘sourcing’ vs ‘sinking’, and ‘voltage’ vs ‘current’ for analog models.

The Programming Device and Human-Machine Interface

Outside of the PLC itself are two very important components: the programming device and the human-machine interface (HMI). The programming device can be a desktop computer, laptop, or hand-held instrument from the same manufacturer. Some small PLCs even have buttons on the front which allow very basic logic operations to be programmed without the need for a computer.

While the programming device allows the user to view and modify the code running on the PLC, the HMI provides a method of displaying information and obtaining inputs, modeling the control system as a whole. HMIs do not typically provide any way to modify the logic program.

Figure 3 shows an HMI touchscreen that can be used in the control room or out in the “field” closer to the process. These types of interactive displays are very common and will often be mounted directly on the PLC enclosure or nearby for operator use.

Figure 3. Some touch panels can interact with the process or simply monitor the control system. Image used courtesy of Phoenix Contact

Before modern HMIs, plant operators relied on walls of analog gauges and light bulb indicators to understand the state of their processes. Opening a valve to let off pressure in a pipe or ramping down a temperature control loop could not be done from a computer in the control room, but instead had to be radioed to an outside operator who performed the action manually. Contrast these control rooms of old against modern control rooms, equipped with HMIs and advanced graphics.

Summary

Automation and control engineers design this high-level view of the PLC. These engineers understand control systems, control algorithms, and configuration. They model the process and determine the size and scale of the system needed. From there, the PLC and all of its components are purchased. This could be a single rack with eight I/O cards, or twenty racks all communicating over an industrial network with thousands of I/O points – all of the control being done by a single CPU.

Copyright Statement: The content of this website is intended for personal learning purposes only. If it infringes upon your copyright, please contact us for removal. Email: admin@eleok.com